1. Why does the cutting fluid corrode aluminum products?

Aluminum corrosion is divided into chemical corrosion and electrochemical corrosion. Aluminum is corroded in weak acid (less than 4.5) or strong alkali (greater than 8.5).

Prevent chemical corrosion: The cutting fluid itself is alkaline. The pH of the good cutting fluid is less than 8.5, and an aluminum corrosion inhibitor is added. Also, the alkaline additive in the cutting fluid will also produce a yellow spot after air drying on the surface of the aluminum workpiece, which is also corrosion.

Electrochemical Corrosion: The processed product should not be placed on iron plates or iron products, and with cutting fluid, it is easy to produce electrochemical corrosion.

2. The difference between aluminum cutting fluid and metal cutting fluid

Metal cutting fluids generally have emulsions, kerosene, and diesel oil, and the range of choice is relatively large; aluminum cutting fluids generally use kerosene or kerosene paraffin solution. The advantage of using kerosene or kerosene in aluminum cutting fluids is that the chips are not easy to be cut by a knife, and the finished workpiece has a better finish. Milling aluminum parts and other cutting fluids are not as effective as kerosene.

In fact, it seems that there is no difference, the performance is similar, have anti-corrosion, anti-rust, cooling, environmental protection and other properties. Also widely used in stainless steel, mold. Only the aluminum product cutting fluid is relatively tested for aluminum alloy, and it is also easy to use in aluminum alloy, and the effect is also obvious, and the metal cutting fluid can be used on the metal cutting fluid.

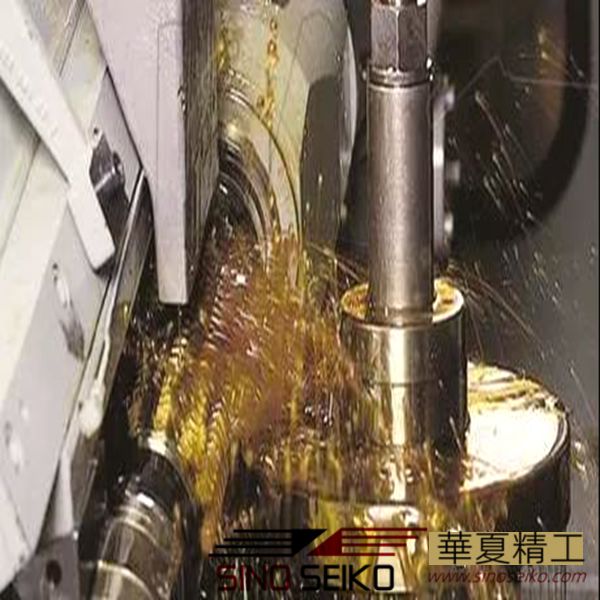

3. Classification and use of emulsified cutting fluid and synthetic cutting fluid

The synthetic cutting fluid does not contain mineral oil and is composed of water-soluble rust inhibitors, oily agents, extreme pressure anti-wear additives, surfactants, preservatives and defoamers. The diluent is transparent or translucent. It has excellent cooling and cleaning performance, is suitable for high-speed cutting; solution is transparent, has good visibility, and is especially suitable for use in modern processing equipment such as CNC machine tools and machining centers, and has a long service life.

The concentrate of the emulsion is mainly composed of mineral oil or synthetic oil (content 50% - 80%), emulsifier, rust inhibitor, oil agent, extreme pressure anti-wear additive and preservative. When the concentrate is used, it is directly diluted with water to form an emulsion, and the diluent is opaque and milky white.

4. Selection of cutting fluid when cutting stainless steel

The selection principle of cutting fluid must meet the requirements of cutting performance and performance. It should have good lubrication, cooling, anti-rust and cleaning performance. It can meet the process requirements during processing, reduce tool loss, reduce the surface roughness and reduce the surface roughness. Power consumption and increase production efficiency. At the same time, the stability of use should be considered. Therefore, the selection of cutting fluid should follow the following principles:

1) The cutting fluid should have no irritating odor, no harmful additives to the human body, and ensure the safety of the user.

2) The cutting fluid should meet the requirements of equipment lubrication and protection management, that is, the cutting fluid should not corrode the metal parts of the machine tool, and will not damage the machine seals and paint, and will not leave hard gelatinous deposits on the machine guide rails, ensuring the use of equipment. Safe and working properly.

3) The cutting fluid should meet the anti-rust requirements between the workpiece processes and not rust the workpiece. Sulfur-containing cutting fluids should not be used when processing copper alloys. When processing aluminum alloy, the cutting fluid with a neutral pH should be used.

4) The cutting fluid should have excellent lubricity and cleaning performance. The cutting fluid with high load value and small surface tension was selected and tested by the cutting fluid test.

5) The cutting fluid should have a long service life, which is especially important for the machining center.

6) The cutting fluid should be adapted to a variety of processing methods and a variety of workpiece materials.

7) The cutting fluid should be low in pollution and have a waste liquid treatment method.

8) Cutting fluid should be cheap and easy to prepare.

Therefore, when selecting the cutting fluid, the user can first select 2 to 3 kinds of cutting fluids with better comprehensive performance according to the specific processing conditions of the enterprise. After the actual trial, determine the performance to meet the processing requirements, and the price is suitable for cutting. The performance of the liquid workpiece material is important for the choice of cutting fluid.

Contact: Sino Seiko

Phone: +8613353772661

Tel: +8613353772661

Email: [email protected]

Add: Zhengzhou, Henan, China