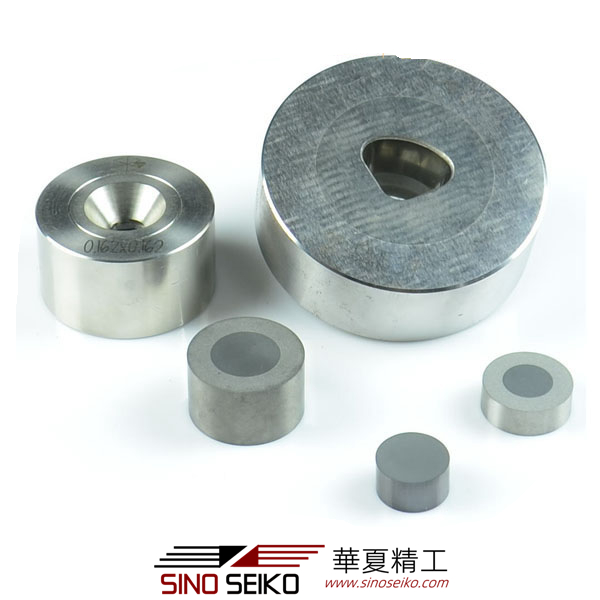

Sinoseiko located in Zhengzhou——The biggest diamond industrial area in the world. Cooperated with outstanding manufactures and the most advanced PCD Die Blanks For Wire Drawing performance test lab in China. This enables Sinoseiko to provide our customers with practical solutions for their PCD Die Blanks For Wire Drawing needs..With more than 20 years developing in this industry, Sinoseiko had witnessed the first manufacture of PCD die blanks manufacturer established in Zhengzhou, China, and Zhengzhou has been the manufacturers worldwide who can produce super large PCD die blanks biggest size in Φ40mm by 25mm height. Till now, Sinoseiko PCD has been used in many countries and areas, and is well received by customers for longer service life, precision wire, and competitive prices.

Applications:

Copper wire, Aluminum wire, Stainless steel wire, Coated stainless steel wire, Tungsten wire, Molybdenum wire, Welding wire, Large diameter tubes etc.

Advantages:

1. Sinoseiko can supply full sizes die blanks from D6 to D36+, from 1 micron to 50 micron grain size.

2. Sinoseiko can supply self supported die blanks, heat-resistant die blanks, and tungsten carbide supported die blanks.

3. Sinoseiko PCD can be used in hard wires drawing.

4. Sinoseiko PCD has better D-D bonding, which makes PCD more compact and uniform, can achieve high abrasion resistance, anti-cracking.

5. Sinoseiko has short lead time.

6. Sinoseiko has competitive prices.

|

ADDMA No. |

Product No. |

Dimensions (mm) |

Concentricity (mm) |

Grain size(μm) |

Maximum recommended hole size(mm) |

||

|

∅D(Total dia)

|

∅d(Diamond)

|

t(Thickness)

|

|||||

|

D12 |

415SP |

8.12 |

4.2 |

1.5 |

0.25 |

3,5,10,25 |

1.0 |

|

D15 |

423SP |

8.12 |

4.2 |

2.3 |

0.25 |

3,5,10,25 |

1.8 |

|

D18 |

429SP |

8.12 |

4.2 |

2.9 |

0.25 |

3,5,10,25 |

2.3 |

|

D21 |

638SP |

13.65 |

6.9 |

4.0 |

0.35 |

3,5,10,25 |

3.5 |

|

D24 |

653SP |

13.65 |

6.9 |

5.3 |

0.40 |

3,5,10,25 |

4.6 |

|

D27 |

1270SP |

24.13 |

12.9 |

7.5 |

0.50 |

5,10,25 |

5.4 |

|

D27 |

1285SP |

24.13 |

12.9 |

9.0 |

0.50 |

5,10,25 |

5.8 |

|

D30 |

1212SP |

24.13 |

12.9 |

12.0 |

0.50 |

5,10,25 |

7.6 |

|

D30 |

1512SP |

24.13 |

15.6 |

12.1 |

0.50 |

10,25 |

9.0 |

|

D33 |

1515SP |

24.13 |

15.6 |

15.1 |

0.50 |

10,25 |

10.5 |

|

D30 |

1813SP |

30.0 |

18.3 |

13.5 |

0.60 |

25 |

11.2 |

|

D33 |

1815SP |

30.0 |

18.3 |

15.5 |

0.60 |

25 |

12.0 |

|

D36 |

1818SP |

30.0 |

18.3 |

18.5 |

0.60 |

25 |

12.7 |

|

|

2518SP |

50.0 |

25.0 |

18.0 |

0.70 |

25 |

14.0 |

|

|

2520SP |

50.0 |

25.0 |

20.0 |

0.70 |

25 |

15.7 |

|

|

3020SP |

50.0 |

30.0 |

20.0 |

0.70 |

25 |

17.0 |

|

|

3022SP |

50.0 |

30.0 |

22.0 |

0.70 |

25 |

19.0 |

|

|

4025SP |

67.0 |

40 |

25.0 |

0.70 |

25 |

25.7 |

|

Online Chatting |

||

|

Mr. Ma |

Mr. Bruce |

Miss. Ann |

|

|

|

Contact: Sino Seiko

Phone: +8613353772661

Tel: +8613353772661

Email: [email protected]

Add: Zhengzhou, Henan, China